General description

Wire straightening machines for cut test are used to produce steel wire samples to be used for laboratory purpose (for example to produce samples for the tensile test).

Wire straightening machines for cut test manufactured by Promostar are single unit able to straight sample of the steel wire after the hot rolling, cold rolling or stretching process.

In the wire sample straightening machine, the sample of the wire to be straightened is taken cutting a portion of hot rolled wire during the spooling phase for reproduce the straightening process carried out in processing steel centers.

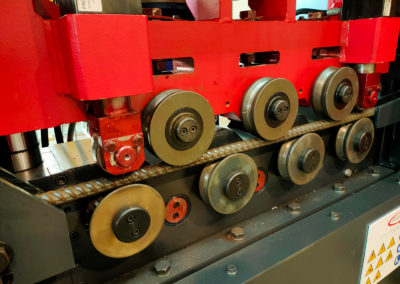

The machine consists of n° 4 lower motorized rollers and n° 3 upper idle rollers, vertically adjustable (according to the wire diameter to be straightened), which function is to deform the material beyond its elastic range, obtaining the straightening.

Wire straightening machines for cut test are used to produce steel wire samples to be used for laboratory purpose (for example to produce samples for the tensile test).

Wire straightening machines for cut test manufactured by Promostar are single unit able to straight sample of the steel wire after the hot rolling, cold rolling or stretching process.

In the Wire straightening machines for cut test, the sample of the wire to be straightened is taken cutting a portion of hot rolled wire during the spooling phase for reproduce the straightening process carried out in processing steel centers.

The machine consists of n° 4 lower motorized rollers and n° 3 upper idle rollers, vertically adjustable (according to the wire diameter to be straightened), which function is to deform the material beyond its elastic range, obtaining the straightening.

The three upper idle rollers, mounted on a mobile frame laterally guided by guides, in addition to be individually adjustable in the vertical direction, are brought into working position by an hydraulic cylinder that contrasts the component of vertical thrust due to the action of deformation of the material during the advancement.

Thanks to an alternate process of straightening made with these motorized and idle rolls, the machine produces straight bars ready to be used for the laboratory machines.

The horizontal movement of the material takes place through the activation of the lower rollers by means of a motor gearbox fixed to the base.

Normally, the pieces produced, are used to feed the tensile test equipment’s to check the mechanical properties of the ribbed wire rod produced in the hot rolling mill process but can feed any kind of machine that requires the use of straight bars of wire material.

Tecnical specifications

| Working speed (max) | 13 m/min |

|---|---|

| Wire diameter | 8 ÷ 25 mm |

| Wire quality | low carbon wire rod |

| Length of the sample | half spiral (~ 1,5 meters) |

| Radius of curvature of the sample | 600 ÷ 700 mm |

| Temperature of the sample | ambient temperature |