welded wire machine just in time ltg

Just In Time Ltg

for the civil and industrial construction

General description

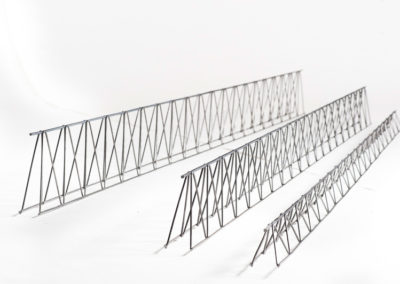

Welded wire machine Just in Time LTG is our solution to produce electro-welded lattice girders to be used in products as reinforcing for the civil and industrial construction, foundations and precast industry.

Welded wire machine Just in Time LTG combines the process of electro welding (through welding heads) with the cutting to the length and the lattice girders.

In the field of the plants for the production of lattice girder, Promostar has developed the patented model (European Patent EP 07 150 103.5) JitLGP (Just in time Lattice Girder Plant) which is designed, in particular, to be incorporated into carousel systems for the production of prefabricated slabs.

Specifically born to meet the requirements of the fully automatic prefabrication plants, the JitLGP line, in the version HF (High Flexibility), is capable to produce continuously single girders with geometrical characteristics which can automatically change from girder to girder (in 10 seconds maximum).

Welded wire machine Just in Time LTG is our solution to produce electro-welded lattice girders to be used in products as reinforcing for the civil and industrial construction, foundations and precast industry.

Welded wire machine Just in Time LTG combines the process of electro welding (through welding heads) with the cutting to the length and the lattice girders.

In the field of the plants for the production of lattice girder, Promostar has developed the patented model (European Patent EP 07 150 103.5) JitLGP (Just in time Lattice Girder Plant) which is designed, in particular, to be incorporated into carousel systems for the production of prefabricated slabs.

Specifically born to meet the requirements of the fully automatic prefabrication plants, the JitLGP line, in the version HF (High Flexibility), is capable to produce continuously single girders with geometrical characteristics which can automatically change from girder to girder (in 10 seconds maximum).

The shape and engineering details of the line allow to produce high-quality product according to the geometrical shape and dimensions requested by the customers. The final product does not require further processing and is ready to be used in the concrete applications.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machine is the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

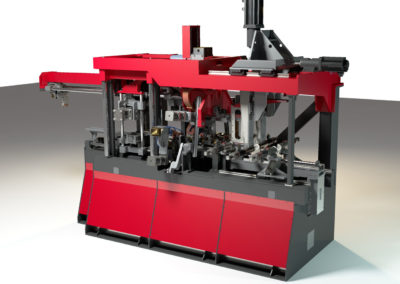

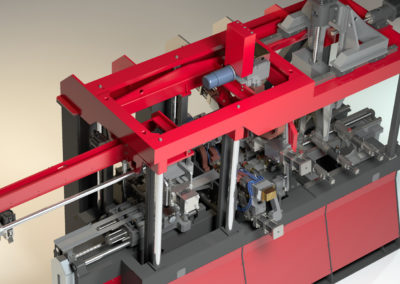

The Just in time LTG machine is composed by two main parts.

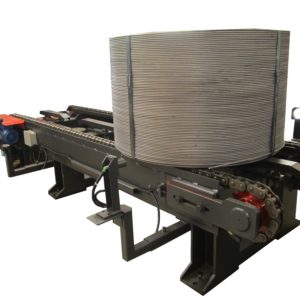

The first part of the machine is the feeding system. The automatic straightening and cutting machine is designed to produce straightened cut-to-length bars starting from wire in coils to feed the Just in time LTG main body. The system is equipped to process coils or spools of smooth and/or ribbed cold drawn/rolled wire as well as of hot rolled wire. The prominent feature of this machine is that it has a number of independent straightening lines, one for every different wire diameter category that the client wishes to process. There is also a completely automatic diameter change system for each line (which takes only a couple of seconds). It is composed by several pay-off units whose numbers depends on the number of straightening lines needed followed by a wire straightening and cutting system.

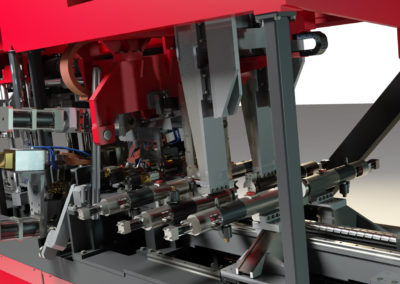

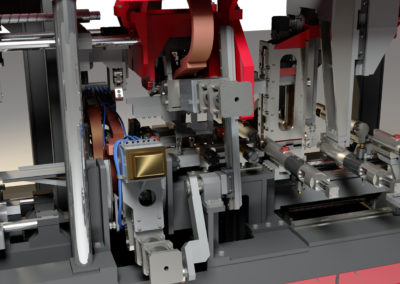

The second part is the JitLTG body machine. Feed by the first part of the line it consists in two main groups: the forming group and the welding group. The forming group permits the shaping of the stirrup with the just in time variation of the height, on the ground of the desired lattice girder. The welding group thanks to a resistance electro-welding process permits the welding of the stirrups to the longitudinal bars, assuring an accurate positioning through a sophisticated guide system. The control of the upper longitudinal bar’s position permits to obtain a finished product complying with the set up geometrical parameters. The peculiarity of the Promostar welding system consists in the just-in-time orientation of the welding bases that are always parallel to the layer upon which the stirrup lies; this layer changes its inclination on the ground of the lattice girder height’s variation. An advancement carriage permits the advancement, step by step, of the lattice girder while a shear allows the cutting of the finished produced lattice girders.

In case of continuous production of lattice girder with constant dimensions (diameter of longitudinal wires, height of the lattice girders and diameter of the stirrup wire) it’s possible to operate in a traditional way (not just in time but in continuous), introducing bars of maximum possible length in the machine and performing the cut at the exit of the machine, instead of on the forming pliers present in the forming group.

This kind of machine is part of our division of special machine and obviously it can be customized upon the request of our customers based on the different shapes and dimensions of the final products (the design starts from the final product to be produced).

Due to the special final products to realize, all the technical information reported are to be considered as indicative and we suggest to contact us for further details.

Technical specifications

| Upper longitudinal bar diameter | from 5 to 16 mm |

|---|---|

| Lower longitudinal bar diameter | from 8 mm to 16 mm |

| Lattice girder height (min-max) | from 70 to 140 mm |

| Lattice girder length (min-max) | from 800 to 20000 mm |

| Stirrup wire diameter | from 4 mm to 9 mm |

| Bending pin diameter | 20 mm |

| Pitch | variable 190 to 210 mm |

| Wire quality | smooth or ribbed low carbon wire |

| Welding speed | up to maximum 60 cycles/min |

Highlights

- Capable to produce continuously single girders with geometrical

characteristics which can automatically change from girder to girder (in 10

seconds maximum). - Engineered to works in just in time modality or traditional (continuous

production). - Welding orientation of the bases that are always parallel to the layer upon

which the stirrup lies. - Remote control assistance kit.

- Simple maintenance procedure and fast set-up of the machine.

- Smart design of the line in terms of layout dimensions.

- Customizable according to the customer needs.