Cold wire drawing line

Maiastar DV

for smooth wire drawing coils

General description

Cold wire drawing line Maiastar DV is the perfect line to produce smooth wire drawing rolls or coils, to be used in products as annealed wire, fencing mesh, spring wire, nails, galvanized wire, for industrial and agricultural market.

Cold wire drawing line Maiastar DV combine the drawing process of the wire rod with the spooling of the cold drawing wire to the desired coil weight.

The shape and engineering details of the line allow to produce high-quality cold drawing coils with excellent mechanical and geometrical properties. The final product can feed any type of machine.

The Maiastar DV machine is our standard solution for the production of cold drawing steel wire coils.

Cold wire drawing line Maiastar DV is the perfect line to produce smooth wire drawing rolls or coils, to be used in products as annealed wire, fencing mesh, spring wire, nails, galvanized wire, for industrial and agricultural market.

Cold wire drawing line Maiastar DV combine the drawing process of the wire rod with the spooling of the cold drawing wire to the desired coil weight.

The shape and engineering details of the line allow to produce high-quality cold drawing coils with excellent mechanical and geometrical properties. The final product can feed any type of machine.

The Maiastar DV machine is our standard solution for the production of cold drawing steel wire coils.

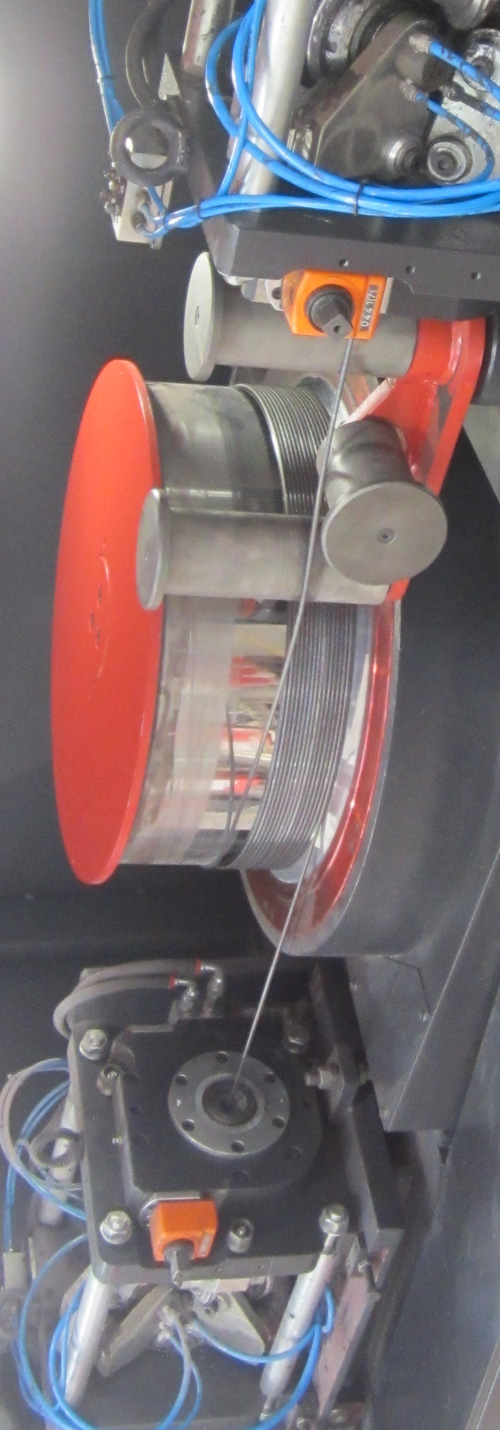

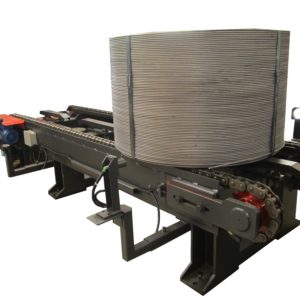

The core of the machine is the Maiastar body that consists in a series of interconnected modular inclined capstan blocks with vertical axes, whose motion is regulated and synchronized by a self-centering dancer arm. The number of capstan blocks depends on the final wire diameter to produce starting from 3 up to 15 pulling bullblocks. This machine, also known in the market as multi-pass machine can produce smooth wire up to Ø1mm minimum size and a weight capacity of the rolls or coils up to 3 tons.

The wire rod, pulled by the high-performances bullblock and driven by the PLC of the last generation, is cold rolled by the die drawing boxes or by the rolling cassettes or by a combination of both (one device for each capstan blocks) that reduce the diameter to the desired size improving the mechanical properties and the roundness of the wire.

An efficient water-cooling system at atmospheric pressure internally cools the capstan.

Each capstan surface is also individually air cooled by a fan, mounted inside each block, which in conjunction with an annular conveyor produces an added air-cooling effect on the wire wound on the capstan.

The complete multipass line is mechanically and electrically designed to permit the production of exit wires without utilizing all the bullblocks present in the line.

All the electric, hydraulic and lubrication systems are conveniently arranged inside the machine in order to simplify the maintenance of the line.

The machine body is protected by a mobile totally enclosed guards that incorporate contacts for limit switches which interlock electrically the line and automatically stop the line if the protective structures are opened during normal (automatic) operation. The guards have been designed to permit an easy access for the maintenance phases and a complete visibility while the line is in operation.

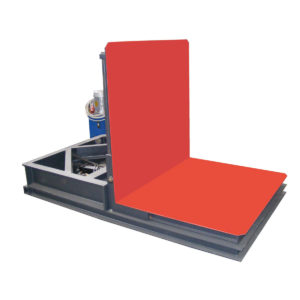

At the beginning of the machine a payoff system with a vertical pay-off tower with two tilting fingers, is used to feed the machine with the plain wire produced in the hot mill process.

Other devices, like mechanical descaler are included.

At the exit, a static coiler deadblock machine or a wire spooler machine with horizontal or vertical axes realizes the winding of the wire on the spools.

In the highest level of automation of our plants, the above mentioned machine can be equipped with an automatic vertical wire spoolers that make all the operations like insertion of the wire, cutting, change of the spools, samples taking, strapping, labeling and weighing of the coils without any intervention of the operator.

The shape and engineering details of our lines allow to produce high-quality cold roll coils packaged in fixed or take a part spools with adjustable weight up to 8 tons. Normally, the coils produced are used for the production of annealed wire, fencing mesh, spring wire, nails, galvanized wire, for industrial and agricultural market.

Technical specifications

| Inlet Wire Diameter | 5,5 ÷ 10 mm |

|---|---|

| Wire quality at entrance | low carbon wire rod |

| Outlet wire diameter | 1 ÷ 8 mm |

| Type of wire at exit | smooth wire coils/spools |

| Coil weight (max) | Up to 3 tons |

Highlights

- Descaler rolls can automatically and directly adjustable by receipt from control pulpit.

- Possibility to use different models of die drawing boxes: fixed, rotating or motorized.

- Possibility to use rolling cassettes at the place of the die drawing boxes.

- Possibility to works without using all the bullblocks present in the line.

- Capstans water-cooling system under pressure plus an additional cooling system with fan.

- Remote control assistance kit.

- Automatic greasing system for rolling cassettes.

- Simple maintenance procedure and fast set-up of the machine.

- Smart design of the line in terms of layout dimensions.

- Customizable according to the customer needs.