Cold rolling line

Librastar

for steel wire coils, smooth, ribbed or indented

General description

Cold rolling line Librastar is the perfect line to produce cold roll steel wire coils, smooth, ribbed or indented, to be used in products as reinforcing welded mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Cold rolling line Librastar combine the cold rolling process of the wire rod with the spooling of the cold rolled reinforced wire to the desired coil weight.

The shape and engineering details of the line allow to produce high-quality cold roll coils with excellent mechanical and geometrical properties of the ribbed profile. The final product can feed any type of welding reinforcing mesh machine or cut and bend equipment.

Cold rolling line Librastar is the perfect line to produce cold roll steel wire coils, smooth, ribbed or indented, to be used in products as reinforcing welded mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Cold rolling line Librastar combine the cold rolling process of the wire rod with the spooling of the cold rolled reinforced wire to the desired coil weight.

The shape and engineering details of the line allow to produce high-quality cold roll coils with excellent mechanical and geometrical properties of the ribbed profile. The final product can feed any type of welding reinforcing mesh machine or cut and bend equipment.

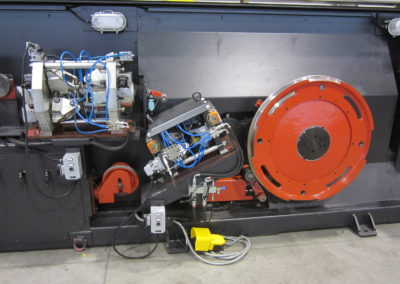

The Librastar machine is our standard solution for the production of cold roll steel wire coils.

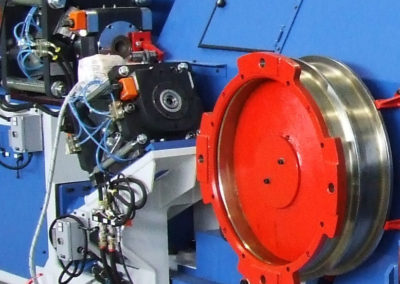

The core of the machine is the Librastar body. Inside there is the bullblock with horizontal axis, equipped with the wire drawing capstans (possibility to install up to 4 capstans) and is able to produce cold roll steel wire coils with a diameter range from Ø4 to Ø20mm and a weight capacity up to 8 tons.

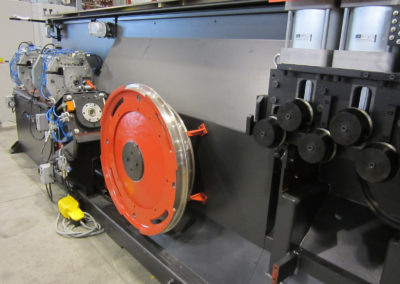

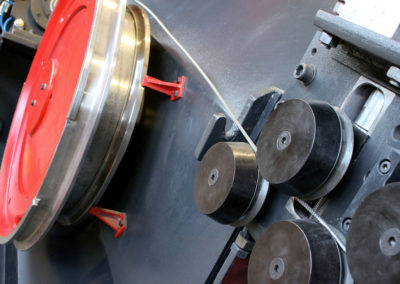

The wire rod, pulled by the high-performances bullblock and driven by the PLC of the last generation, is cold rolled by the rolling cassettes (with the possibility to install up to three rolling cassettes) that reduce the diameter to the desired size improving the mechanical properties and adding the positive ribbing or the negative indentation to the wire.

The machine can be also equipped with stretching panels (at the place of rolling cassettes) to produce stretched wire starting from rebar in coil material.

All the electric, hydraulic and lubrication systems are conveniently arranged inside the machine in order to simplify the maintenance of the line.

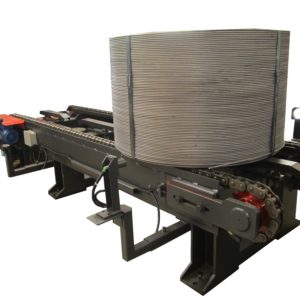

At the beginning of the machine a payoff system (with a vertical pay-off tower with two tilting fingers or with an horizontal pay-off beam, according to the wire sizes) is used to feed the machine with the plain wire produced in the hot mill process.

Other devices, like mechanical descaler or wire drawing lubricant machine are included.

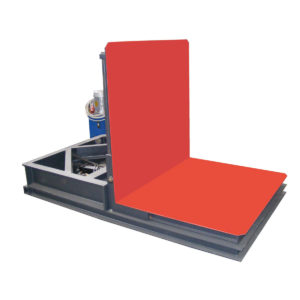

At the exit, a wire spooler machine with horizontal or vertical axes realizes the winding of the wire on the spools.

In the highest level of automation of our plants, the above mentioned machine can be equipped with an automatic vertical wire spoolers that make all the operations like insertion of the wire, cutting, change of the spools, samples taking, strapping, labeling and weighing of the coils without any intervention of the operator.

The shape and engineering details of our lines allow to produce high-quality cold roll coils packaged in fixed or take a part spools with adjustable weight up to 8 tons. Normally, the coils produced are used for reinforcing mesh, stirrups, cages and lattice girders for the civil and industrial construction, foundations and precast industry.

Technical specifications

| Outlet wire diameter | 4 ÷ 20 mm |

|---|---|

| Type of wire at exit | ribbed or indented wire coils/spools |

| Coil weight (max) | Up to 8 tons |

Highlights

- Descaler rolls can automatically and directly adjustable by receipt from control pulpit.

- Possibility to use 1, 2 or 3 rolling cassettes together (according to the requested reduction scale).

- Stress relieving device to improve mechanical characteristics (tensile strength, ductility, elongation) that can be installed in up or down position: while down, the pulling force is made by the bullblock and not by the spooler.

- Engineered for cold rolling and/or stretching process, with fast changing and settings.

- Horizontal bullblock, can be equipped with there (3) smooth capstans plusone (1) shape capstan for stretching that doesn’t require to be dismounted for production changing (drawn or stretched wire).

- Double locking clamp for wire (one at the exit of Librastar and one at the entry of the automatic spooler), so the wire is always kept tensioned even in case of break (to guarantee a good quality winding).

- Remote control assistance kit.

- Automatic greasing system for rolling cassettes, stretching panels and stress relieving rolls.

- Possibility to install a dust conveyor integrated system, using conveyors below the payoff and main units.

- Simple maintenance procedure and fast set-up of the machine.

- Smart design of the line in terms of layout dimensions.

- Customizable according to the customer needs.