Welded wire machines

Machines and wire equipments

General description

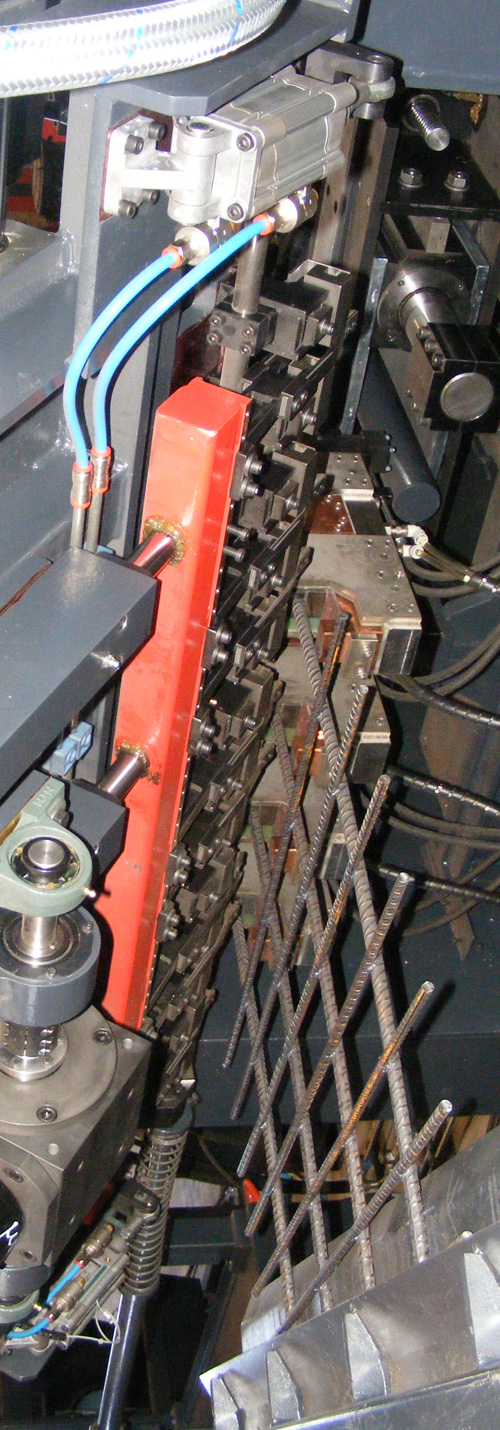

Welded wire machines are used to produce different shapes of products made with smooth, indented or ribbed wire starting from coils and/or from bars.

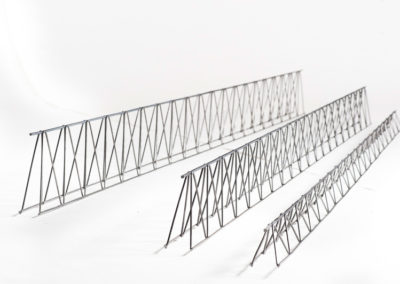

Welded wire machines are designed based on the final product applications, which are special products like straight spacers (used as spacers between the row of the walls bricks), bended spacers (used in the concrete floor or brick slab as spacers for the welding wire meshes), tunnel mesh elements (used in the tunnel sections), lattice girders for reinforced concrete and other special shaped customized solutions.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machines are the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

Welded wire machines are used to produce different shapes of products made with smooth, indented or ribbed wire starting from coils and/or from bars.

Welded wire machines are designed based on the final product applications, which are special products like straight spacers (used as spacers between the row of the walls bricks), bended spacers (used in the concrete floor or brick slab as spacers for the welding wire meshes), tunnel mesh elements (used in the tunnel sections), lattice girders for reinforced concrete and other special shaped customized solutions.

Compared to manual manufacturing methods, the advantages of this kind of automatic welding wire machines are the productivity, greater flexibility and rapidity in production changes of the diameter sizes, the quality and the repeatability of the product, the limited number of operators (usually only one operator controls the whole plant) and the production and maintenance costs.

Thanks to more than 40 years of experience in the field of process of rolling, we manufacture high performances automatic turn key plants, that are tailor made on the needs of our customers in terms of layout, products sizes, mechanical properties, level of automation and which allow to finally reduce the transformation costs for each tons of steel wire produced.

Our offer is not limited to the construction of machines and equipment. If required, we are also able to supply valid training, technical assistance and consulting to improve the production; These services are the keys to reach the target and maintain it over time in terms of efficiency and performance of the plant as well as in terms of correct dimensional and geometrical tolerance of the final products.

Technical specifications

| Longitudinal wire number | Up to 6 |

|---|---|

| Longitudinal wire diameter | Starting from 3 mm |

| Transversal wire number | Up to 2 |

| Transversal wire diameter | Starting from 3 mm |

| Welding speed (max) | Up to 70 cycles/minute |

| Wire quality at entrance | low carbon wire rod |

Final products

Our welded wire machines

Our WELDED WIRE MACHINES are the followings:

WELDED WIRE MACHINE BLOCK MESH

WELDED WIRE MACHINE JUST IN TIME LTG

WELDED WIRE MACHINE TUNNEL MESH

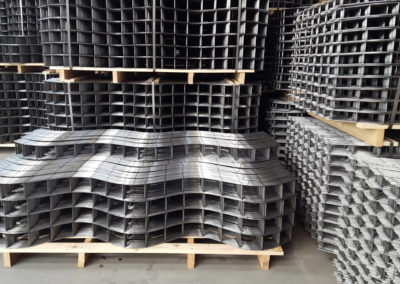

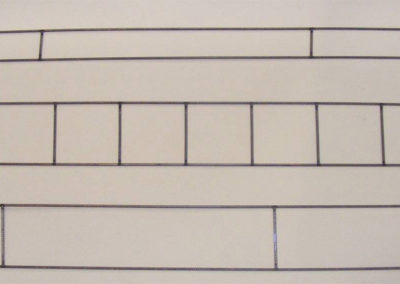

The Block Mesh is our solution to produce straight spacers (used as spacers between the row of the walls bricks) and bended spacers (used in the concrete floor or brick slab as spacers for the welding wire mesh). We have different level of customization: starting from the basic solution where the machine can produce only straight spacer up to the high level solution where the machine can produce straight and bended spacer up to two pieces (identical) at the same time.

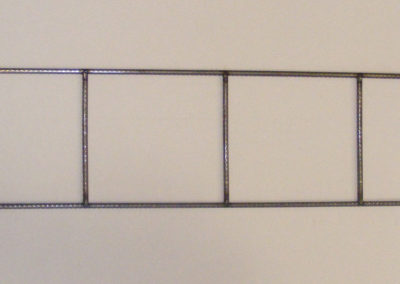

The Just in time LTG is our automatic machine for the production of lattice girders for reinforced concrete where it is required a high flexibility and rapidity in the production changes. It is suggested for the customer that have small lot of pieces to produce but they have to change very often the dimension and the shape of the final product.

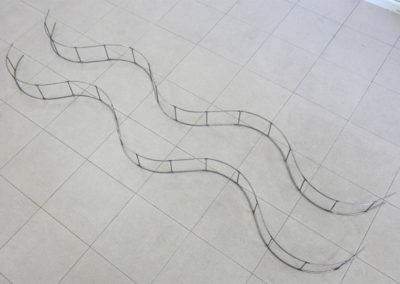

The Tunnel Mesh is our solution dedicated to the production of the tunnel mesh elements that are used in the tunnel sections of the precast industry.

All this kind of machines are part of our special machines division and obviously there are customized upon the request of our customer based on the different shapes and dimensions of the final products (the designing of these machines starts from the final product to be produced).

Depending on the machine, in the higher level of customization the lines can be equipped with automatic tying and palletizing unit at the exit for the automatic creation of sub-bundles and bundles and /or for the unload of the piece over a pallet, in the storage area of the factory.

For further information on these machines please click on the links above. Due to the specificities and so the absence of a real standard of the final products to realize, please consider all the following technical information just as indicative and contact directly us for any technical details.